The RSD range is available from 12ft (3.6m) to 32ft (9.6m). It features a fixed frame and adapter plate system.

The models are designed to suit the requirements to harvest rice, hemp and grass seed.

RSD Range Crop Suitability

Rice

Harvesting rice presents a unique set of challenges, high moisture, high yields and tough separation conditions. The RSD stripper header’s unique design helps rice producers gain better returns by improving harvesting performance. The benefits of using the stripper header in rice are capacity gained through increased ground speed. It is quite common to increase a combines capacity by up to 50 to 100%. This is achieved by decreasing straw intake into the combine and generally making the combine’s job easier. Productivity increases of 100% can be achieved when harvesting in adverse conditions such as down rice.

Grasses

The RSD stripper header has revolutionized harvest for many grass seed producers around the world. The strippers ability to comb lodged crops of ryegrass and fescue off the ground and strip the seed without taking much of the green stem into the combine increases harvesting efficiency by up to 50%. Because the combine no longer has to process so much foreign material the seed recovery rates generally improve.

Hemp

Shelbourne stripper headers have been used globally for harvesting hemp leaves, flowers & buds for a number of years. The action of the stripping rotor combs through the fibrous stalk removing the seeds, buds & leaves with little damage to the fragile crop and therefore maximizing the CBD oil content available.

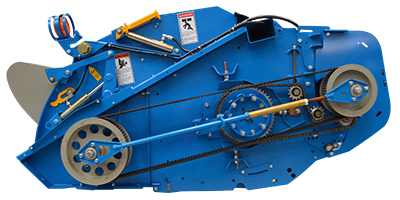

RSD - High Torque Drive System (HTD)

The RSD models utilize the proven High Torque Drive system, the drive transmits maximum power to the stripping rotor via a high torque timing belt. The speeds can be adjusted by swapping a combination of 3 pulleys and tensioning the belt by adjusting the pivoting gearbox which maximizes the overall belt wrap. Its overall design is simple and requires minimal maintenance.

The speed of the rotor and the auger are displayed on the monitor in cab which includes an alarm system to aid the operator.

Features

- High torque timing belt

- 4 speed ranges

- 3 pulleys 56t, 64t & 72t

- Sprung pivoting gearbox for belt tension

- Minimal maintenance

- In cab monitor & alarm system

RSD Range Standard Features

RSD Stripper Header Range Benefits

The RSD is fitted with a fixed speed belt drive system wheras the RVS is fitted with a variable speed belt drive system.

Harvesting Efficiency

The use of a RSD stripper header increases the capacity of the combine by an average of 50%.

The stripper header delivers predominantly grain into the combine which improves productivity and decreases losses.

Crop Recovery

The RSD header has developed a reputation for improved crop recovery in lodged crop conditions.

Increasing both productivity as well as the volume of crop recovered per acre. The rearwards rotating rotor with 8 rows of stainless steel fingers acts like a pick-up attachment and is able to lift lodged crop off of the ground, the header then strips the grain leaving the majority of the straw behind.

Fuel Saving

Combines use considerable power to first thresh then separate grain from straw and then chop the straw.

The use of a stripper header uses considerably less power as the combine is no longer processing straw. Operators have reported average fuel savings of 30% There is also less wear on the combine as it is no longer handling as much material.

Improved Milling Grade In Rice

Improved milling grades are common with the use of a stripper header because the header does the majority of the threshing and the combine settings can be less aggressive.

Improved Seed Sample In Grass Seed

By reducing the level of foreign material intake the cleaning systems efficiency improves resulting in improved seed samples.

Simple, Durable Construction

Because of the aggressive nature of rice the RSD range is constructed in a way to offer greater protection against wear in critical areas by the use of materials such as stainless steel.

The 8 rows of stripping fingers also utilize the benefits of stainless steel for maximum durability and longevity. The overall design has simple aspects where the numbers of moving parts are minimized to keep routine maintenance easy. Each machine is put through a thorough test procedure before it leaves the factory

RSD 3D View

The use of a RSD or CVS stripper header increases the capacity of the combine by an average of 50%.