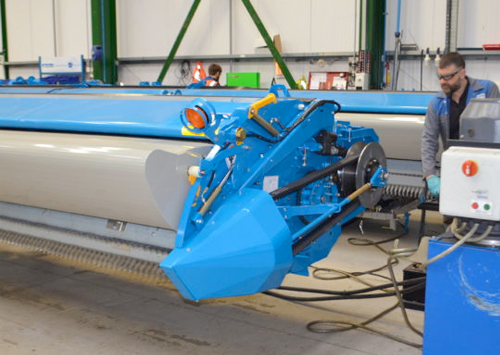

The X range consists of 3 models XCV, XCS & XRS and is available from 32ft (9.6m) to 42ft (12.6m).

The models feature a spring loaded pivoting adapter plate system which enable the wider heads follow the ground contours.

The headers are all centrally mounted and therefore compatible with controlled traffic applications.

X Range Crop Suitability

Cereal Crops

XCV & XCS Models are Suitable for Cereals

Wheat

Barley

Oats

Flax / Linseed

Field Peas

Rice

XRS36 Model is Suitable for Rice

Harvesting rice presents a unique set of challenges, high moisture, high yields and tough separation conditions. The XRS stripper header’s unique design helps rice producers gain better returns by improving harvesting performance. The benefits of using the stripper header in rice are capacity gained through increased ground speed. It is quite common to increase a combines capacity by up to 50 to 100%. This is achieved by decreasing straw intake into the combine and generally making the combine’s job easier. Productivity increases of 100% can be achieved when harvesting in adverse conditions such as down rice.

X Range Models

XCV

The XCV range is available in 3 widths:

- XCV32 32ft / 9.6m

- XCV36 36ft / 10.8m

- XCV42 42ft / 12.6m

The heavy duty variable speed drive system is suited for harvesting cereal grains which allows the operator to adjust the stripping rotor speed from the comfort of the cab throughout the day.

The machine incorporates 3 stripping rotor’s with two equally spaced division plates. this means that the rotors are shorter and are able to operate smoother with greater reliability.

The sprung loaded adapter plate system which when coupled to the spring loaded gauge wheels enables the header to follow the ground contours.

Central mounted to be compatible with modern controlled traffic operations.

Features

- Heavy Duty Variable Speed Drive

- Sprung Mounted Adapter Plate

- 2 adjustable gauge wheels

- 3 Piece Stripping Rotor

- In cab monitor / alarm

- 10 Spring Auger Clutch

XRS

The XRS is available in one width XRS36 – 36ft (10.8m) which is centrally mounted.

The drive system comprises of a high torque timing belt with interchangeable pulleys.

The spring loaded pivoting adapter plate system which provides lateral movement to aid with uneven ground conditions / laid crop recovery.

Because of the aggressive nature of rice the XRS range is constructed in a way to offer greater protection against wear in critical areas by the use of materials such as stainless steel.

Features

- 36ft / 10.8m Width

- High torque drive system

- Sprung Mounted Adapter Plate

- 3 Piece Stripping Rotor

- 2 Piece Auger

- In cab speed monitor / alarm

- 10 Spring Auger Clutch

- Stainless steel construction in high wear areas

XCS

The XCS range is available in 3 widths:

- XCS32 32ft / 9.6m

- XCS36 36ft / 10.8m

- XCS42 42ft / 12.6m

The drive system comprises of a high torque timing belt with interchangeable pulleys.

The machine incorporates 3 stripping rotor’s with two equally spaced division plates. this means that the rotors are shorter and are able to operate smoother with greater reliability.

The sprung loaded adapter plate system which when coupled to the spring loaded gauge wheels enables the header to follow the ground contours.

Central mounted to be compatible with modern controlled traffic operations.

Features

- High torque drive system

- Sprung mounted adapter plate

- 2 adjustable spring gauge wheels

- 3 Piece Stripping Rotor

- In cab speed monitor / alarm

- 10 Spring auger clutch

- Minimal maintenance

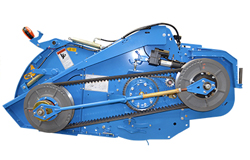

XCV - Variable Speed Drive System

The XCV utilizes the proven variable speed belt drive system, rotor speed is adjusted with an electric actuator on the drive pulley in conjunction with a posi-torque spring tension system fitted to the front pulley.

The in cab monitor allows the operator to adjust the speed of the stripping rotor by controlling an electric actuator that adjusts the drive pulley. The speed of the rotor and the auger are displayed and includes an alarm system to aid the operator.

Features

- Heavy Duty Pozi Torque Drive Pulley

- 3 Spigot rear pulley

- Speed Range 420-800rpm

- Electric Actuator Control

- In cab monitor & alarm system

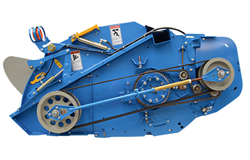

XCS & XRS - High Torque Drive System

The XCS & XRS models utilize the proven High Torque Drive system, the drive transmits maximum power to the stripping rotor via a high torque timing belt. The speeds can be adjusted by swapping a combination of 3 pulleys and tensioning the belt by adjusting the pivoting gearbox which maximizes the overall belt wrap. Its overall design is simple and requires minimal maintenance.

The speed of the rotor and the auger are displayed on the monitor in cab which includes an alarm system to aid the operator.

Features

- High torque timing belt

- 4 speed ranges

- 3 pulleys 56t, 64t & 72t

- Sprung pivoting gearbox for belt tension

- Minimal maintenance

- In cab monitor & alarm system

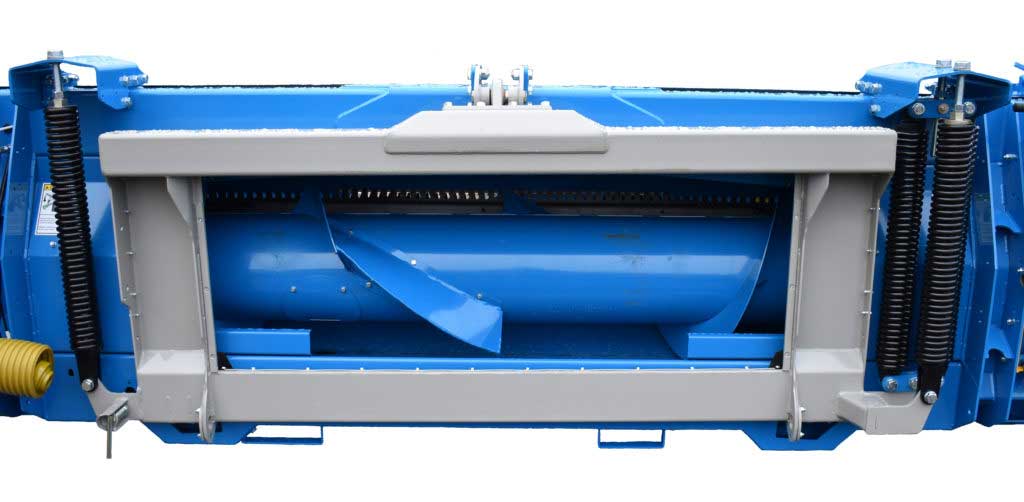

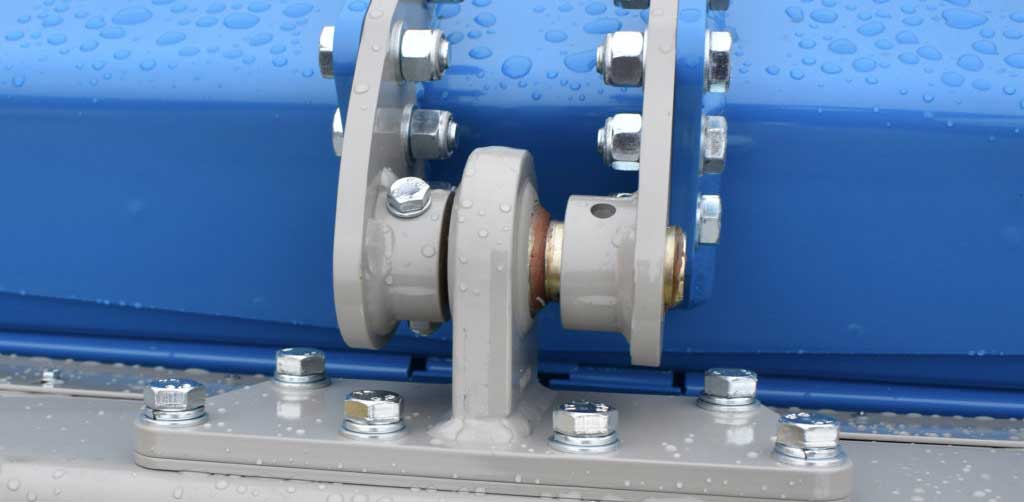

Adapter Plate System

The adapter plates are designed to suit most brands of Combine.

The X range adapter incorporates a central pivot & springs. The springs are to both level the header and apply the desired resistance to the lateral movement.

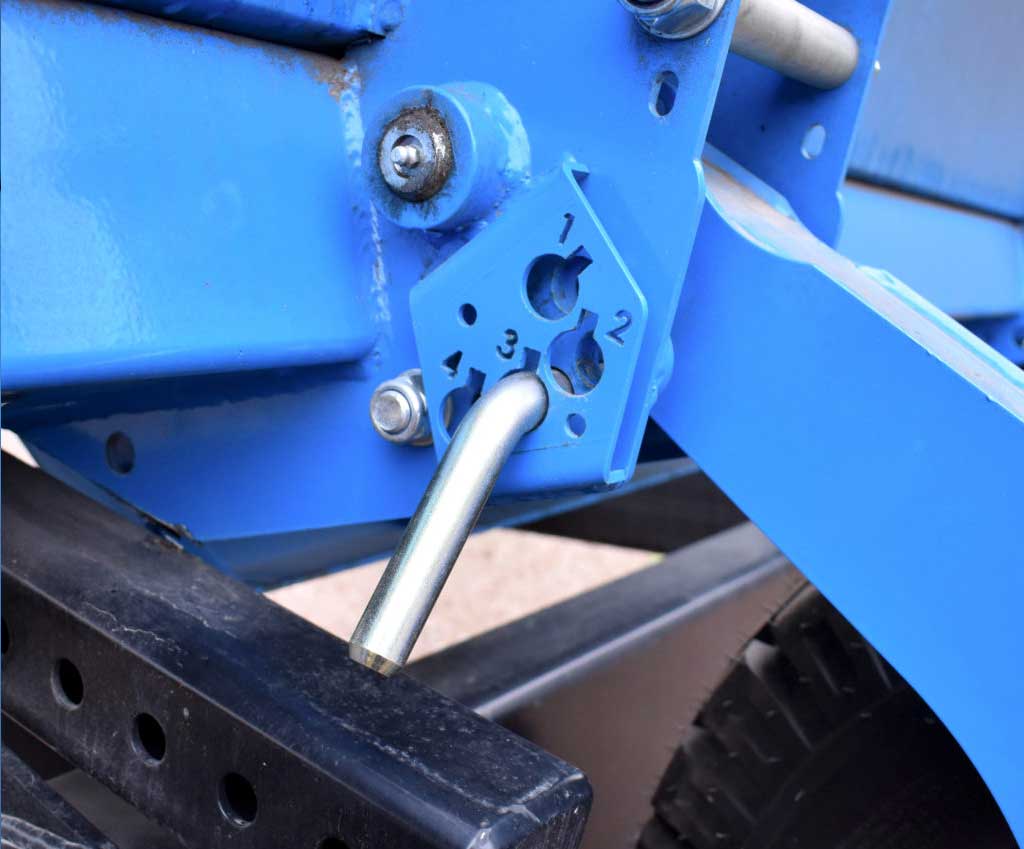

The locking pin allows the header to be locked or allow lateral movement.

Gague Wheels (XCV & XCS)

The XCV & XCS Headers are fitted with spring loaded gauge wheels.

The top pin is to adjust the pressure on the spring according to crop height (A-E). This can also be used for transport to hold the wheel in a raised position with the pin below the arm.

The bottom pin is to adjust the height of the wheel when the header is raised at the headland (1-4).

X Range Standard Features

X Stripper Header Range Benefits

Harvesting Efficiency

The use of a XCV stripper header increases the capacity of the combine by an average of 30% and delivers predominantly grain into the combine which improves productivity and decreases losses.

Crop Recovery

The XCV header has developed a reputation for improved crop recovery in hailed, lodged and weed infested crops resulting in increased productivity and volume of crop recovered per acre. The rotors selective stripping action leaves green weeds behind.

Fuel Saving

Combines use considerable power to first thresh then separate grain from straw and then chop the straw. The use of a stripper header uses considerably less power as the combine is no longer processing straw and has reported average fuel savings of 30%.

Better Quality Grain

The XCV range stripper header threshes the majority of the grain in the header. This means that the combine’s threshing system can be run slower and is less aggressive on the grain.

Harvest Earlier

Improved Double Cropping

Increased Soil Moisture

Simple, Durable Construction

The XCV range is constructed using premium materials for wear resistance where required. The machine design is simple and uses a minimum number of moving parts for easy maintenance.

RSD 3D View

The use of a XCV stripper header increases the capacity of the combine by an average of 30%.